By Brooklyn Kiosow, Marketing Communications Manager at Formic.

Across the U.S., manufacturers are racing to meet growing demand for products. But with too few people to fill critical production roles, many are turning to temporary labor, overtime, and outsourcing just to keep up. On the production floor, employees are feeling the physical toll: lifting, stacking, and packing more boxes than ever to keep products flowing.

Temporary labor and overtime, however, are a short-term fix for a long-term problem in manufacturing facilities across the U.S. That’s why more business leaders are turning to automation to close labor gaps and reduce downtime that limits output. And as manufacturers automate, something else is happening downstream: the maritime industry is getting busier than ever.

Unlike factories, ports don’t face a shortage of workers. While the manufacturers Formic talks to are often in a never-ending cycle of “hiring-retraining-churning” and repeat, ports have a backlog of qualified people waiting for their opportunity to get started. What they do face, however, is a surge in volume. As American manufacturing grows stronger and more resilient through automation, ports are now handling more goods than ever before. That growth is driving a parallel wave of automation across maritime operations.

According to recent forecasts, the global market for robotics in the maritime industry is projected to reach $9.8 billion by 2030, nearly doubling from $5 billion in 2025. That’s not because companies are replacing people. It’s because they’re equipping them with better tools to handle the sheer volume of work that today’s world demands.

What’s Driving Maritime Automation Today

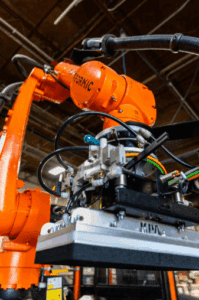

Across the maritime industry, many sectors are already investing in automation. In shipbuilding, robots and automated systems handle welding, assembly, and quality inspection. At ports, autonomous or remotely operated cranes streamline cargo handling and transport. In subsea operations, autonomous underwater vehicles (AUVs) gather critical data for mapping and inspection. Even onshore, robots are being used for repetitive or ergonomically difficult tasks like stacking containers, inspecting cargo holds, or maintaining ship equipment, ultimately helping the high volume of available employees avoid injury and focus on higher-impact work.

As automation speeds up operations, it’s also improving safety: robots can take on the more dangerous tasks of inspecting hulls, performing maintenance in hard-to-reach areas, and operating in more hazardous conditions. This reduces the need for workers to take on risky assignments, but it doesn’t replace the need for human hands to manage the massive amount of products flowing through these locations.

In warehouses near ports, automated palletizers and case packers are helping teams keep pace with record volumes without physical strain or overtime burnout. Automation serves as a force multiplier for the maritime industry, not as a replacement for human labor.

Charting the Next Phase of Maritime Automation

Ports are being asked to do more than ever and move faster than ever before. With limited physical space to expand, the question becomes: how can they make the most of every square foot?

The answer lies in the options that support human workers. Automation gives port employees the tools to focus on oversight, strategy, and maintenance rather than repetitive motion.

With certified forklift and crane operators hard to come by, automated guided vehicles (AGVs) are an ideal option to help workers avoid fatigue, streamline processes, and reduce bottlenecks. Beyond logistics, Full Service Automation models make it easier for port warehouses and nearby manufacturers to adopt robotics without major capital costs, giving maritime operations the flexibility to scale as volumes grow.

Automation isn’t just a response to labor challenges; it’s a catalyst for growth across the entire supply chain, helping people work smarter and safer as global trade accelerates. The maritime industry has the opportunity not just to keep up when it comes to automating, but to lead.

Brooklyn Kiosow is the Marketing Communications Manager at Formic, she wrote this for American Maritime VOICES.

Come Aboard

"*" indicates required fields